The research has been sponsored by the NSF, DOE, Caterpillar, John Deere, Hyundai, Brunswick, and the University of Illinois ($15M to date 2021).

- 2022-2024 Brunswick

- 2021-2023 DOE

- 2021-2022 Brunswick

- 2021-2023 DOE REMADE

- 2019-2020 John Deere

- 2018-2019 John Deere

- 2017-2018 John Deere

- 2016-2017 John Deere

-

2016-2017 Hyundai Motor Co.

- 2015-2016 John Deere

- 2014-2015 John Deere

- 2013-2014 John Deere

- 2012-2013 John Deere

- 2011-2012 John Deere

- 2010-2011 John Deere

- 2010-2015 NSF CAREER Award

- 2010 NSF Grant

- 2009-2012 NSF GOALI Grant

- 2008-2010 DOE/Sandia National Lab

- 2007-2010 NSF Grant

- 2007-2008 Caterpillar Grant

Green profit design: enabler for sustainable design and manufacturing

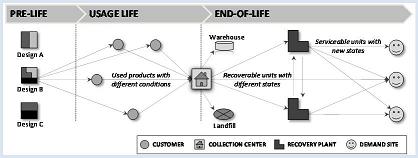

We develop foundations for modeling the link between product design

(pre-life) and take-back and recovery (end-of-life) and evaluating

which design is better than others and why. Our framework can analyze

how architectural differences affect product recovery and what design

properties are desirable from the end-of-life perspective. Using the

framework, designers can answer the question, ``which product design is

better and why from the whole life cycle perspective.”

Ultimately, they can find optimal product design with greater recovery

profit.

Application areas: consumer electronics (cell phone, personal

computers, etc.), automotive vehicles, military combat systems, heavy-duty equipment, and

building design.

Data-driven design analytics: trend-mining design

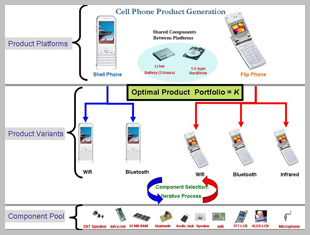

The goal of a firm to produce a portfolio of products is to maximize the profit while meeting the needs of customers. This product design and development process is modeled as a hierarchical decision making process. Research agenda includes predictive data mining for demand analysis, innovative new product concept generation, and green, environmentally conscious design.

Application areas: green product design and manufacturing, product family design and optimization, product pricing and production planning, production scheduling, and reconfigurable/changeable system design.

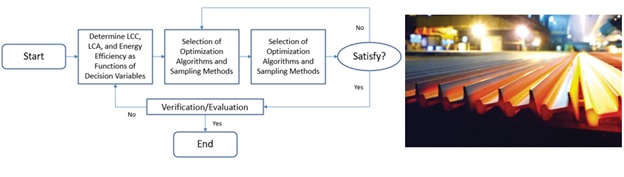

Advancing the sustainable design and manufacturing of complex products

The overarching aim of this research on product design sustainability

is to integrate life cycle costing (LCC) and life cycle assessment

(LCA) in consideration of uncertainty and demonstrate the effectiveness

of trade-off design approach for realistic product (re)use,

(re)manufacturing and (re)cycling cases. The focus is particularly made

on modeling the process of environmental impact assessment and

automating trade-offs in a user-friendly environment.Application areas: heavy-duty equipment, household automation solution, precision agriculture and building design.

Design analytics for product family optimization with supply chain configurations

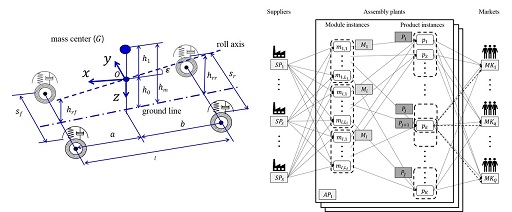

We

develop a sampling-based methodology that optimizes the structure of a

product family with simulation models and the supply chain

configuration simultaneously. It utilizes an idea of finding solution

spaces in a set-based design. The methodology includes a new sampling

technique that collects well-spread feasible points over the design

space of simulation models and problem formulations for product family

optimization. The research provides an optimal selection of components

that maximizes the commonality and minimizes the cost. Applications: Automotive vehicle design, component sharing in product family design, modular design, global manufacturing

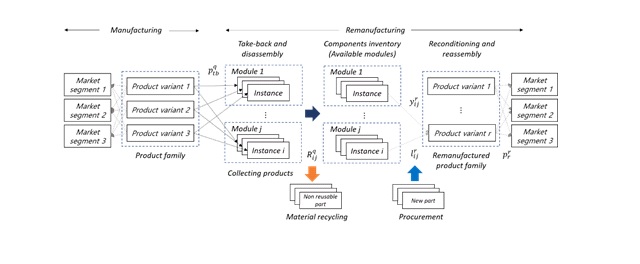

Multi-generational product family design optimization for sustainability

We develop methodologies for product family design optimization for circular business activities instead of the current linear economy. Although a circular economy is presented as an interesting alternative to current linear economic practices, there are also widespread concerns that have grown with its success, such as supply uncertainty, cannibalization of sales of new product, technological obsolescence, and reliability. The purpose of these studies is to identify the effectiveness of circular economic activities by considering these barriers and to propose an optimization model to determine a product family design for profit and environmental goals from an integrated perspective, including manufacturing and remanufacturing. These analyses enable decision makers and product designers to actively identify the benefits and environmental impacts of product line designs. It also helps determine effective parts and platform sharing among the product family.Application areas: Heavy duty and off-road equipment, Motor vehicle parts, Industrial machinery, Information technology (IT) equipment, Consumer electronics and household appliances, Aerospace, and other goods.

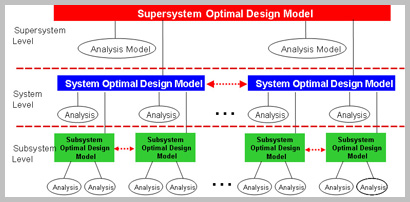

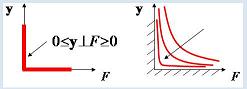

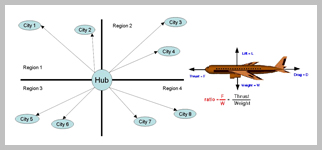

Multidisciplinary design optimization (Analytical Target Cascading)

For large-scale system design, traditional all-in-one approach is not feasible due to its complexity. Based on decomposition and coordination theories, multidisciplinary design optimization (MDO) approaches have been successful to address issues related to the multidisciplinary design. Built upon Analytical Target Cascading (Kim, 2001), research agenda include developing coordination strategy based on Lagrange dual formulation, propagation of uncertainties in hierarchical formulation, transformation of hierarchical approaches to non-hierarchical approaches, and mathematical programming with equilibrium constraints.

Application areas: automotive and consumer electronics portfolio design, changeable/dynamic system design such as automotive engine and deduster, and dual-use (civilian/military) system design.

ATC framework

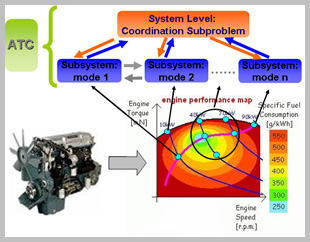

Energy systems engineering and design informatics -

conventional,

renewable, or hybrid energy generation, conversion, and distribution

We develop a dynamic multi-mode design methodology for an efficient energy conversion system. The research will characterize and model key design aspects of an engineering system that must undergo multiple operating conditions, formalize the design methodology, and validate the methodology in a realistic energy conversion system design case. The design methodology utilizes the idea of equilibrium (or complementarity) constraints in a multidisciplinary design optimization framework. The research provides and validates a new class of problems and solutions for dynamic multi-mode system design that is emerging from the energy conversion system design practices in industry, including alternative energy sources.

Application areas: diesel engine, wind energy generation, hybrid energy generation combining multiple sources.

Energy material innovation: Induction-coupled ThermoMagnetic Processing (ITMP)

We have conducted a comparative life cycle assessment on steel production between

using conventional method and using ITMP method (Induction-coupled Thermomagnetic Processing).

In addition, based on the literature review, we have conducted a life cycle assessment on the

production of Niobium Titanium (NbTi), from the stage of ore extraction to that of product

completion. Even though the production of NbTi incurs some negative environmental impact initially,

this initial negative environmental impact will be made up by the preserved energy due to the

application of ITMP method in the long run. That is, the environmental impact caused by NbTi production will

be spread out and recovered, because steel production is much greener with ITMP.

Application areas: green product manufacturing, thermomagnetic processing, heavy industry.

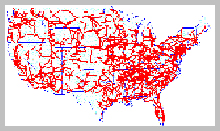

System of systems optimization for product, process and service

design

We aim at developing a holistic modeling methodology that captures the system of systems as a dynamic transient entity rather than static compilation of single systems. Research agenda includes analyzing choice behavior of customers, modeling preference/demand, designing product for operations, and planning multistage design and operations.

Application areas: transportation system, health care, product family design (cellular phones, hand tools, brake system), vehicle routing problem, flow management problem, quality in manufacturing and transactions, hierarchical design under uncertainty, system entity protection and recovery.

Concurrent Design for Aircraft and Routing

System of Systems Optimization e.g. US Electric Power Grid and Combat Systems

Journal publications

Harrison Kim has published over 150 peer-reviewed items in ASME, AIAA, IEEE, Design Society, and INCOSE.

J72. Park, S., Lin, K., Joung, J. and Kim, H. M. "A data-driven approach for product design strategies to respond to market disruption following COVID-19," Under review, 2023.

J71. Park, S. and Kim, H. M. "Extracting product design guidance from online reviews: An explainable neural network-based approach," Expert Systems with Applications, 236, 121357, 2024.

J70. Joung, J. and Kim, H. M. "Interpretable machine learning-based approach for customer segmentation for new product development from online product reviews," International Journal of Information Management, 70 (2023) 102641, 2023.

J69. Park, S. and Kim, H. M. "Analysis of brand effects in data-driven design based on online reviews," Transactions of ASME: Journal of Mechanical Design, 145(12): 121704, 2023.

J68. Park, S. and Kim, H. M. "Finding Social Networks Among Online Reviewers for Customer Segmentation," Transactions of ASME: Journal of Mechanical Design, 2022.

J67. Saidani, M., Joung, J., Kim, H. M., and Yannou, B. "Combining life cycle assessment and online customer reviews to design more sustainable products - Case study on a printing machine," Procedia CIRP, 109 (2022) 604-609, 2021.

J66. Park, S., Joung, J. and Kim, H. M. "Spec guidance for engineering design based on

data mining and neural networks," Computers in Industry, 2023.

J65. Saidani, M., Cluzel, F., Leroy, Y., Pigosso, D., Kravchenko, M., and Kim, H. M., "Nexus Between Life Cycle

Assessment,

Circularity, and Sustainability Indicators—Part II: Experimentations," Circular Economy and Sustainability, 2022.

J64. Saidani, M., and Kim, H. M., "Nexus Between Life Cycle Assessment, Circularity,

and Sustainability Indicators—Part I: a Review," Circular Economy and Sustainability, 2022.

J63. Kim, J., Park, S., and Kim, H. M. "Optimal Modular Remanufactured Product

Configuration and Harvesting Planning for End-of-Life Products," Transactions

of ASME: Journal of Mechanical Design, 144(4): 042001, 2022.

J62. Joung, J. and Kim, H. M. "Explainable neural network-based approach to kano

categorisation of product features from online reviews,"International Journal of Production Research, 60:23, 7053-7073, 2023.

J61. Saidani, M., Cluzel, F., Yannou, B., and Kim, H. M. "Circular economy as a key for industrial

value chain resilience in a post-COVID world: what do future engineers think?," Procedia CIRP, 103 (2021) 26–31, 2021.

J60. Park, S. and Kim, H. M. "Phrase Embedding and Clustering for Part-level

Feature Extraction from Online Data," Transactions

of ASME: Journal of Mechanical Design, 2021.

J59. Kim, J., Park, S., and Kim, H. M. "Analysis of Dynamic Changes in Customer

Sentiment on Product Features After the Outbreak of COVID-19 Based on Online Reviews," Transactions

of ASME: Journal of Mechanical Design, 144(2): 024501, 2022.

J58. Saidani, M., Kim, H. M., and Kim, J., "Designing Optimal COVID-19 Testing Stations Locally:

A Discrete Event Simulation Model Applied on a University Campus" PLoS ONE, Vol. 16, No. 6, 2021.

J57. Joung, J. and Kim, H. M., "Approach for Importance–Performance Analysis of Product Attributes From Online Reviews" Transactions of ASME: Journal of Mechanical Design, 2021.

J56. Joung, J. and Kim, H. M., "Automated Keyword Filtering in Latent Dirichlet Allocation for Identifying Product Attributes From Online Reviews" Transactions of ASME: Journal of Mechanical Design, 2021.

J55. Li, J., Akdeniz, N., Kim, H.M., Gates, R., Wang, X., and Wang, K., "Quantification of sustainable animal manure utilization strategies in

Hangzhou, China," Agricultural Systems, 2021.

J54. Saidani, M., Yannou, B., Leroy, Y. Cluzel, F., and Kim, H. M., "Multi-tool methodology to evaluate action levers to close the loop on critical materials – Application

to precious metals used in catalytic converters," Sustainable Production and Consumption 26 (2021) 999–1010, 2021.

J53. Saidani, M., and Kim, H. M., "A Discrete Event Simulation-Based Model to Optimally Design and Dimension Mobile COVID-19 Saliva-Based Testing Stations," Simulation in Healthcare:

The Journal of the Society for Simulation in Healthcare: April 2021 - Volume 16 - Issue 2 - p 151-152, 2021.

J52. Saidani, M., Pan, E., Kim, H. M., Wattonville, J., Greenlee, A., Shannon, T., Yannou, B., Leroy, Y.

and Cluzel, F. "Comparative life cycle assessment and costing of

an autonomous lawn mowing system with human-

operated alternatives: implication for sustainable

design improvements," International Journal of Sustainable Engineering, 2021.

J51. Kim, J., Saidani, M., and Kim, H. M. "Designing an optimal modular-based product

family under intellectual property and sustainability considerations," Transactions of ASME:

Journal of Mechanical Design, April, 2021.

J50. Saidani, M. and Kim, H. M. "Quantification of the environmental and economic benefits of the electrification

of lawn mowers on the U.S. residential market," International Journal of Life Cycle Assessment, April 2021.

J49. Li, J., Akdeniz, N., Kim, H.M., Gates, R., Wang, X., and Wang, K., "Optimal manure utilization chain for distributed animal farms:

model development and a case study from Hangzhou, China," Agricultural Systems, 2021.

J48. Li, J., Wang, X., Kim, H.M., Gates, R., and Wang, K., "Optimal Design of Manure Management for Intensive Swine Feeding Operation:

A Modeling Method Based on Analytical Target Cascading," Journal of Cleaner Production, Oct. 2020.

J46. Kim, J. and Kim, H. M., "Impact of Generational Commonality of Short

Life Cycle Products in Manufacturing and

Remanufacturing Processes," Transactions of ASME: Journal of Mechanical Design, 142 (12), 2020.

J45. Kim, H.M., Cluzel, F., Leroy, Y., Yannou, B. and Bertoluci, G.,

"Research perspectives in ecodesign," Design Science Journal, Vol. 6, E7,

2020.

J44. Suryadi, D. and Kim, H. M., "A Data-Driven Approach to

Product Usage Context

Identification From Online

Customer Reviews," Transactions of ASME: Journal of Mechanical Design, 141(12),

121104, 2019.

J43. Suryadi, D. and Kim, H. M., "A Data-driven Methodology to

Construct Customer Choice Sets Using Online Data and Customer

Reviews," Transactions of ASME: Journal of Mechanical Design, 141(11),

111103, 2019.

J42. Han, H., Chang, S., and Kim, H. M., "Multiple Target Exploration Approach for Design Exploration Using

a Swarm Intelligence and Clustering," Transactions of ASME: Journal of Mechanical Design, 141(9),

091401, 2019.

J41. Suryadi, D. and Kim, H. M. "A Systematic Methodology Based on Word Embedding for Identifying the Relation between Online Customer Reviews and Sales Rank," Transactions of ASME: Journal of Mechanical Design, 140(12), 1214031, 2018.

J40. Quan, N. and Kim, H. M. "Greedy robust wind farm layout optimization with feasibility guarantee," Engineering Optimization Journal, September 2018.

J39. Kim, H.M., Cluzel, F., Leroy, Y., Yannou, B. and Bertoluci, G.,

"Research perspectives in sustainable design," Design Science Journal, Vol. 6, E7,

2019.

J38. Avrithi, K. and Kim, H. M. "Optimization of Piping Supports and Supporting Structure," Transactions of ASME: Journal of Pressure Vessel Technology,

Vol. 129, No. 4, 2017.

J37. Quan, N. and Kim, H. M. "A Mixed Integer Linear Programing Formulation for Unrestricted Wind Farm Layout Optimization," Transactions of ASME: Journal of Mechanical Design, Vol. 138, 2016.

J36. Kwak, M. and Kim, H. M. "Green Profit Maximization through an Integrated Pricing and Production Planning for a Line of New and Remanufactured Products," Journal of Cleaner Production, 2016.

J35. Kwak, M. and Kim, H. M. "Modeling Time-Varying Advantages of Remanufacturing: Is a ‘Reman’ Better than a ‘Brand New’?," Transactions of ASME: Journal of Mechanical Design, Vol. 138, 2016.

J34. Ma, J. and Kim, H. M. "Predictive Model Selection for Forecasting Product Returns," Transactions of ASME: Journal of Mechanical Design, Vol. 138, 2016.

J33. Ma, J. and Kim, H. M. "Highly Customizable Product Family Design with Predictive, Data-Driven Family Design Method," Research in Engineering Design, pp. 1-17, September, 2015.

J32. Ma, J. and Kim, H. M. "Predictive Usage Mining for Life Cycle Assessment," Transportation Research - Part D, Vol. 38, pp. 125-143, July 2015.

J31. Ma, J. and Kim, H. M. "Continuous Preference Trend Mining for Optimal Product Design with Multiple Profit Cycles," Transactions of ASME: Journal of Mechanical Design, Vol. 136, 2014.

J30. Ma, J., Kwak, M. and Kim, H. M. "Demand Trend Mining for Predictive Life Cycle Design," Journal of Cleaner Production, Vol. 68, pp. 189-199, 2014.

J29. Kwak, M. and Kim, H. M. "Design for lifecycle profit with a

simultaneous consideration of initial manufacturing and end-of-life

remanufacturing," Engineering Optimization Journal, Dec. 2013.

J28. Lu, S. and Kim, H. M. "Wind Farm Layout Design Optimization Through Multidisciplinary Design Optimization with Complementarity Constraints," Engineering Optimization Journal, Vol. 46, No. 12, pp. 1669-1693, 2014.

J27. Kwak, M. and Kim, H. M. "Market Positioning of Remanufactured Products with Optimal Planning for Part Upgrades," Transactions of ASME: Journal of Mechanical Design, Vol. 135, No. 1, 2013.

J26. Rojas, A. and Kim, H. M. "Incorporating Security Considerations Into Optimal Product Architecture and Component Sharing Decision in Product Family Design," Engineering Optimization Journal, Vol. 44, No. 1, pp. 55-74, 2012.

J25. Kannan, A., Shanbhag, U.V. and Kim, H. M., "Addressing supply-side risk in uncertain power markets: stochastic Nash models, scalable algorithms and error analysis," Optimization Methods and Software, 2012.

J24. Kwak, M., Kim, H. M. and Thurston, D. "Formulating

Second-Hand

Market Value as a Function of Product

Specifications, Age, and Condition," Transactions of ASME:

Journal of

Mechanical Design, Vol. 134, No. 3, 2012.

J23. Tucker, C. and Kim, H. M. "Trend Mining for Predictive Product Design," Transactions of ASME: Journal of Mechanical Design, Vol. 133, No. 11, 2011.

J22. Kwak, M., Behdad, S., Zhao, Y., Kim, H. M. and Thurston, D. "E-waste Stream Analysis and Design Implications," Transactions of ASME: Journal of Mechanical Design, Vol. 133, No. 10, 2011.

J21. Kannan, A., Shanbhag, U.V. and Kim, H. M., "Strategic Behavior in Power Markets under Uncertainty," Journal of Energy Systems, Vol. 2, No. 2, 2011.

J20. Rojas, A. and Kim, H. M. "Optimal

Component Sharing in Product

Family by Simultaneous Consideration of Minimum Description Length and

Impact Metric," Engineering Optimization Journal, October, Vol. 43,

No. 2, pp. 175-192, 2011.

J19. Kwak, M. and Kim, H. M. "Assessing Product Family Design from an End-of-Life Perspective," Engineering Optimization Journal, Vol. 43, No. 3, pp. 233-255, 2011.

J18. Ramani, K., Ramanujan, D., Bernstein, W., Zhao, F., Sutherland, J., Handwerker, C., Choi, J., Kim, H. M. and Thurston, D., "Integrated Sustainable Life Cycle Design: A Review," Transactions of ASME: Journal of Mechanical Design, Vol. 132, No. 9, 2010.

J17. Lu, S., Schroeder, N., Kim, H. M. and Shanbhag, U., "Hybrid Power/Energy Generation System Design through Multidisciplinary and Multilevel Design Optimization Problems with Complementarity Constraints," Transactions of ASME: Journal of Mechanical Design, Vol. 132, No. 10, 2010.

J16. Kwak, M. and Kim, H. M. "Evaluating End-of-Life Recovery Profit by a Simultaneous Consideration of Product Design and Recovery Network Design," Transactions of ASME: Journal of Mechanical Design, Vol. 132, No. 7, 2010.

J15. Zhao, Y., Pandey, V., Kim, H. M. and Thurston, D. "Varying Lifecycle Lengths within a Portfolio For Product Take-Back," Transactions of ASME: Journal of Mechanical Design, Vol. 132, No. 9, 2010, 2010. (The conference version won the best paper award in 2009 ASME IDETC/CIE Design for Manufacturing and Life Cycle Conference.)

J14. Lu, S. and Kim, H. M. "A Regularized Inexact Penalty Decomposition Algorithm for Multidisciplinary Design Optimization Problem with Complementarity Constraints," Transactions of ASME: Journal of Mechanical Design, Vol. 132, No. 4, 2010.

J13. Behdad, S., Kwak, M., Kim, H. M. and Thurston, D. "Simultaneous Selective Disassembly and End-Of-Life Decision Making For Multiple Products," Transactions of ASME: Journal of Mechanical Design, Vol. 132, No. 4, 2010.

J12. Kim, H. M., Lu, S., Kim, B.-D. and Kim, J.-S., "Parallel, Multistage Model for Enterprise System Planning and Design," IEEE Systems Journal, Vol. 4, No. 1, pp. 6-14, 2010.

J11. Tucker, C., Kim, H. M., Barker, D., and Zhang, Y. "A ReliefF attribute weighting and X-means clustering methodology for top-down product family optimization," Engineering Optimization Journal, Vol. 42, No. 7, pp. 593 - 616, 2010.

J10. Tucker, C. and Kim, H. M., "Data-Driven Decision Tree Classification for Product Portfolio Design Optimization," Transactions of ASME: Journal of Computing and Information Science in Engineering, Vol. 9, No. 4, 2009.

J9. Tucker, C. and Kim, H. M., "Optimal Product Portfolio Formulation by Merging Predictive Data Mining with Multilevel Optimization," Transactions of ASME: Journal of Mechanical Design, Vol. 130, pp. 991-1000, April 2008. (Also, a finalist for the best student paper competition in the 11th AIAA/ISSMO MAO Conference, Sept., 2006.)

J8. Kim, H. M., Chen, W., and Wiecek, M., "Lagrangian Coordination for Enhancing the Convergence of Analytical Target Cascading," AIAA Journal, Vol. 44, No. 10, pp.2197 - 2207, 2006.

J7. Liu, H., Chen, W., Kokkolaras, M., Papalambros, P.Y., and Kim, H. M. "Probabilistic Analytical Target Cascading - A Moment Matching Formulation for Multilevel Optimization under Uncertainty," Transactions of ASME: Journal of Mechanical Design, Vol. 128, pp. 991-1000, July 2006 (also presented in 2005 ASME DAC).

J6. Kim, H. M., Kumar, D. K. D., Chen, W., and Papalambros, P. Y., "Target Exploration for Disconnected Feasible Regions in Enterprise-Driven Multilevel Product Design," AIAA Journal, Vol. 44, No. 1, pp. 67-77, 2006.

J5. Cooper, A. B., Georgiopoulos, P., Kim, H. M., and Papalambros, P. Y., "Analytical Target Setting: An Enterprise Context in Optimal Product Design," Transactions of ASME: Journal of Mechanical Design, Vol. 128, No. 1, pp. 4-13, 2006.

J4. Kim, H. M., Rideout, D. G., Papalambros, P. Y., and Stein, J. L., "Analytical Target Cascading in Automotive Vehicle Design," Transactions of ASME: Journal of Mechanical Design, Vol. 125, pp. 474-480, 2003

J3. Kim, H. M., Michelena, N. F., Papalambros, P. Y., and Jiang, T., "Target Cascading in Optimal System Design," Transaction of ASME: Journal of Mechanical Design, Vol. 125, pp. 481-489, 2003.

J2. Kokkolaras, M., Fellini, R., Kim, H. M., Michelena, N. F., and Papalambros, P. Y., "Extension of the Target Cascading Formulation to the Design of Product Families," Journal of Structural and Multidisciplinary Optimization, Vol. 24, Issue 4, pp. 293-301, 2002.

J1. Kim, H. M., Kokkolaras, M., Louca, L., Delagrammatikas, G., Michelena, N. F., Filipi, Z., Papalambros, P. Y., and Assanis, D., "Target Cascading in Vehicle Redesign: A Class VI Truck Study," International Journal of Vehicle Design, Vol. 29, No. 3, pp. 199-225, 2002.

Book Chapters

B3. Kwak, M. and Kim, H. M., "Product Family Design and Recovery for Lifecycle, Advances in Product Family and Product Platform Design (Edited by Simpson, T., Jiao, R., Siddique, Z. and Holtta-Otto, K.), Springer, 2013.

B2. Kumar, D.K.D., Chen, W., and Kim, H. M., "Multi-level Optimization for Enterprise Driven Decision-Based Product Design," Decision Making in Engineering Design (Edited by Lewis, K, Chen, W. and Schmidt, L.), ASME Press, 2006.

B1. Kokkolaras, M., Fellini, R., Kim, H. M., and Papalambros, P.Y. "Analytical Target Cascading in Design of Product Families," Product Platform and Product Family Design: Methods and Applications (Edited by Simpson, T.W., Siddique, Z., Jiao, J.), Kluwer Academic Publishing, New York, 2005.

- Copyright 2005 - Present

- Copyright 2005 - Present